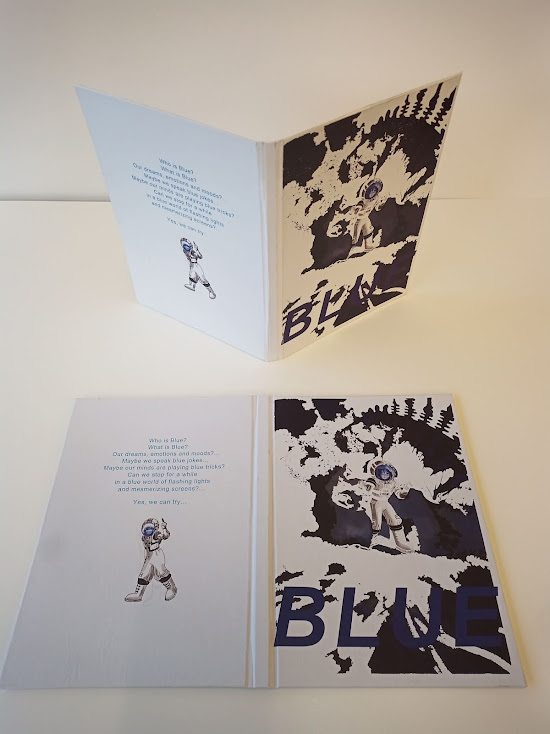

1. BOOK COVERS.

The practice resulted in many errors and mistakes, ripped papers and wrong sizing.

Some of the covers below can be used as an experiment with pop-up pages in the future.

Some of them turned out wrong and uneven, but a good exercise in bookmaking.

2.MOCKUPS

A few mockups were created trying out different layouts, binding methods, paperweight and colours.

I tried two types of Japanese binding, 4-hole and tortoise-shell bind, which I adapted to my preferences by adding more holes. I also tried a bookbinding machine to glue one mockup.It turned out to week for some reason.

Bookbinding machine where I glued additional masking tape on the top. A few pages got loose. I decided not to use the bookbinding machine again.

Testing gate folds layout in one of the mockups.

3. JAPANESE BINDING.

Two copies of the book were sawn twice, first, the inside pages were sawn separately, and then the covers. I thought that way the book will become much stronger. The thickness of the paper was 140gsm and turned out to be too much and sawing was very hard.

4. PERFECT BINDING

Two other copies were put together using this method.

The book is secured with clamps.

The pages are scored with a saw, making 3mm cut into the paper.

Linen threads with bookbinding PVA glue are inserted in the indentations.

A few layers of soft handmade tissues are glued on top of the spine.

The same is repeated with the fourth and the final, so far, copy of the book.

This one has many acetate pages and I worried it might not glue well. I used two types of glue, paper and plastic glue to secure the pages.

5. SLIPCASES AND BOXES.

I made three additional boxes for the books. I used a specialistic bookbinding Buckram cloth to wrap around them.

I was planning to do the fourth one but I run out of time.

This is something I would like to make more of in the future to sell my books as limited editions.

It was an interesting practice, which I haven't done before. It also resulted in minor mistakes.

It's a work in progress and an idea to develop.

The box with the lid turned out a bit too tight in the end. I left it drying overnight with the lid on and a weight on top of it. Because of that, the walls tilted slightly inwards. I also think there was a minor issue with measurements. Trial and error of learning through practice.

Overall, I really enjoyed all the analogue techniques and the final outcomes.

Here are a few photos from the process.

Different type of lighter, metallic Buckram cloth was used throughout the box.

A slipcase cover I sprayed blue inside and use metallic Buckram on the outside.

Comments

Post a Comment